October 15,2025

admin

In project supporting furniture procurement, selecting a reliable office furniture factory is crucial to project success. Many purchasers often encounter issues like delayed deliveries and quality discrepancies due to overlooking key details. Mastering the following 5 details can help you effectively avoid procurement risks and find truly high-quality partners.

1. Verify the Completeness of Qualification Certifications

A high-quality office furniture factory must have a sound qualification system. Focus on checking environmental certifications (such as China Environmental Label Certification) and quality management system certifications (ISO9001), which directly relate to the environmental friendliness and safety of custom office furniture. For project supporting furniture projects, also confirm whether the factory has the qualification to serve large-scale projects to avoid project acceptance issues due to insufficient qualifications. You can request the factory to provide original certification documents and verify their validity period and scope of certification.

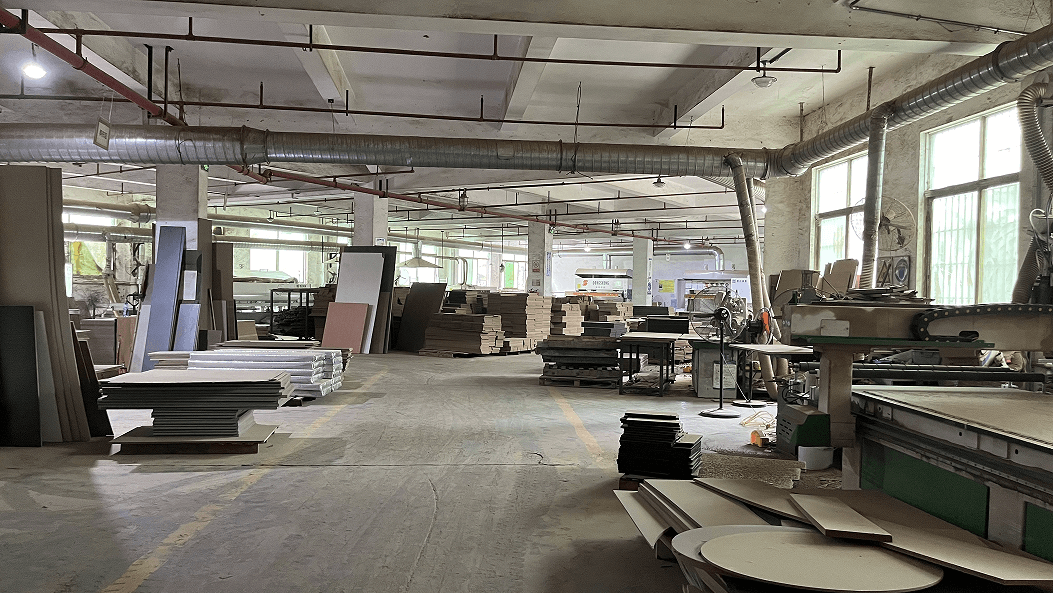

2. Inspect the Authenticity of Production Capacity

During on-site visits to the office furniture factory, focus on the advancement of equipment and production management standards. Observe whether it is equipped with professional equipment such as CNC cutting and automatic edge banding machines, which directly affect the processing precision of custom office furniture. Understand the factory's daily production capacity and maximum order volume to determine if it can meet the delivery schedule requirements for project supporting furniture. Pay attention to the 5S management status in the workshop—neat and standardized production environments often indicate more reliable quality control.

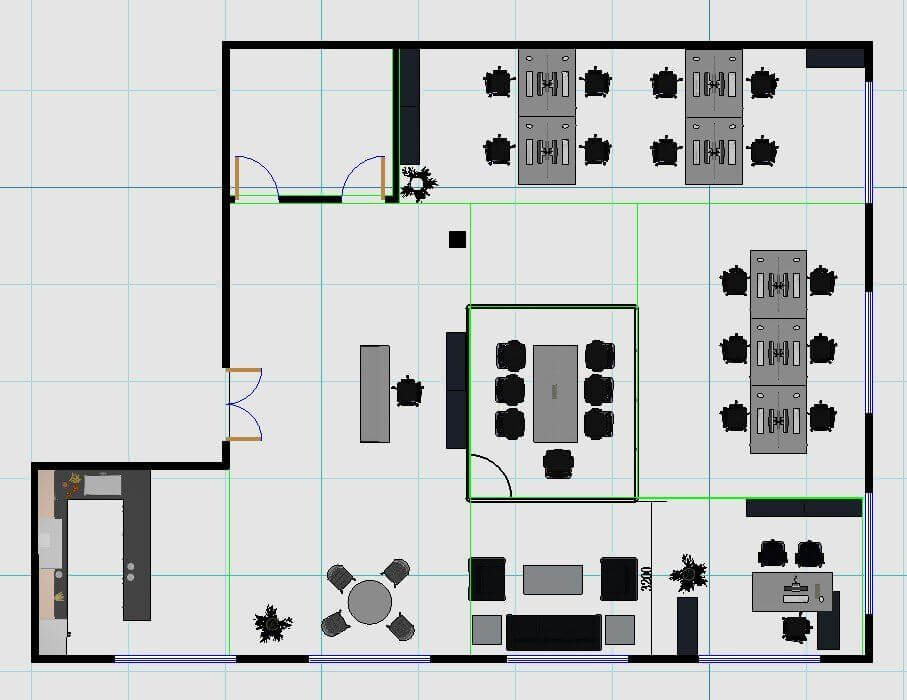

3. Validate the Matching Degree of Engineering Cases

The past engineering case matching experience of an office furniture factory is crucial. Request project cases of similar scale from the past 3 years, and review key contract pages and on-site photos. Focus on verifying the authenticity of the cases; you can request owner contact information for cross-verification. Pay special attention to cases matching your project type, such as project supporting furniture solutions for different scenarios like office buildings and hospitals, to evaluate the factory's scenario adaptation capability.

4. Clarify the Detail of Contract Terms

When signing the contract, detail core clauses such as technical parameters, material standards, and acceptance milestones for custom office furniture. Clearly stipulate the penalty standards for delayed delivery and the return/exchange mechanism for quality discrepancies. For the installation service of project supporting furniture, specify the installation cycle, personnel allocation, and acceptance criteria. Request to attach sealed material samples in the contract as the basis for later acceptance.

5. Confirm the Security of After-Sales Service

A high-quality office furniture factory will provide comprehensive after-sales support. Clarify the warranty period (it is recommended to be no less than 5 years for project supporting furniture) and after-sales response time (within 24 hours). Understand whether regular maintenance services are provided and the supply guarantee capability of accessories. Request the factory to commit to lifelong maintenance support for project supporting furniture to avoid situations where no one is responsible for later problems.

Grasping these details can help purchasers comprehensively evaluate the comprehensive strength of an office furniture factory, effectively reduce various risks in the procurement of custom office furniture and project supporting furniture, and ensure the smooth progress of the project.