October 15,2025

admin

In the field of project supporting furniture, the delivery capacity and quality stability of office furniture factories directly affect the success or failure of projects. Those factories that consistently maintain on-time delivery and stable quality often possess a set of scientific "strength codes," embodied in three dimensions: production systems, quality control mechanisms, and supply chain management.

Flexible Production System: The Underlying Logic of Delivery Guarantee

High-quality office furniture factories generally adopt flexible production line layouts, achieving full-process visualization of production through digital management systems. Targeting the characteristics of large batches and diverse categories of project supporting furniture, factories conduct advance capacity planning and use MES production execution systems to monitor order progress in real-time. When project requirements change, the flexible production system can quickly switch production plans, avoiding the rigidity of traditional production lines. For example, when facing urgent additional orders for conference room furniture, the intelligent scheduling system can automatically optimize processes to ensure the main project delivery remains unaffected.

Full-Process Quality Control Mechanism: The Core Guarantee for Stable Quality

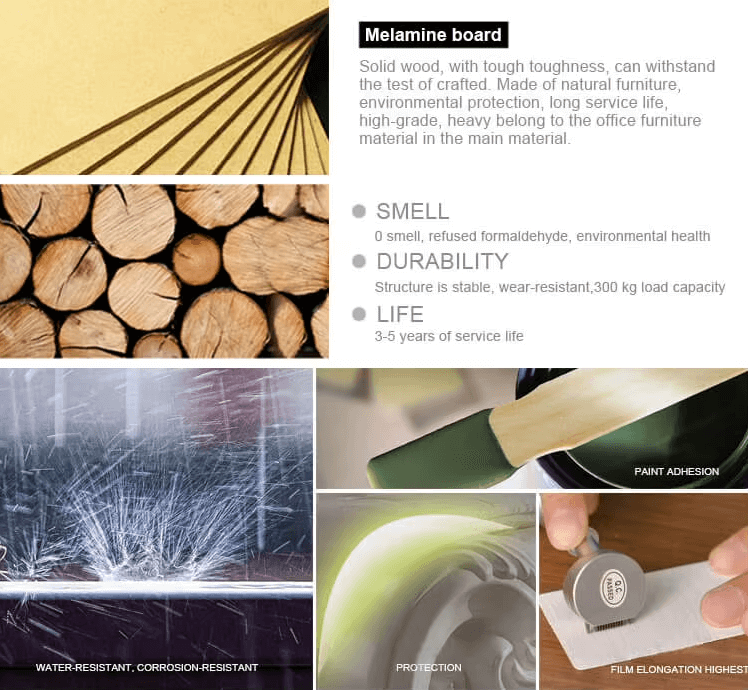

Office furniture factories with stable quality have established a "three-level quality control" system. Raw materials must pass environmental testing and physical performance tests before warehousing to prevent unqualified panels from entering the production line; 12 key quality control points are set during production, with clear standards from cutting precision to hardware installation; finished products undergo on-site simulation assembly tests before leaving the factory to ensure the dimensional error of project supporting furniture is controlled within 2 millimeters. Especially for hidden projects such as internal structural reinforcement of furniture, factories use X-ray flaw detection and other technologies for random inspections to eliminate quality hazards from the source.

In-Depth Supply Chain Integration: The Key Support for Risk Resistance

Office furniture factories with stable delivery often have a cluster of core suppliers with over 5 years of cooperation. They achieve independent control of the supply chain by holding shares in panel processing plants and establishing central warehouses for hardware accessories. For special materials commonly used in project supporting furniture, factories maintain a safety stock of more than 30 days. In logistics, they sign strategic cooperation agreements with professional furniture transportation companies, equipped with customized transport brackets to control long-distance transportation loss rate below 0.5%. This in-depth integrated supply chain system can effectively resist risks such as raw material fluctuations and logistics delays.

Behind these "strength codes" lies the office furniture factory's profound grasp of production laws and technical investment. For project supporting furniture projects, choosing a factory with such a system not only ensures stable delivery but also avoids rework risks caused by quality issues, becoming an important support for the smooth implementation of projects.