October 15,2025

admin

Within the production chain of project supporting furniture, the core competitiveness of high-quality office furniture factories lies in their rigorous production logic. From design blueprints to project implementation, three key stages directly determine the quality and efficiency of final delivery.

1. Needs Deconstruction: The Customization DNA of Project Supporting Furniture

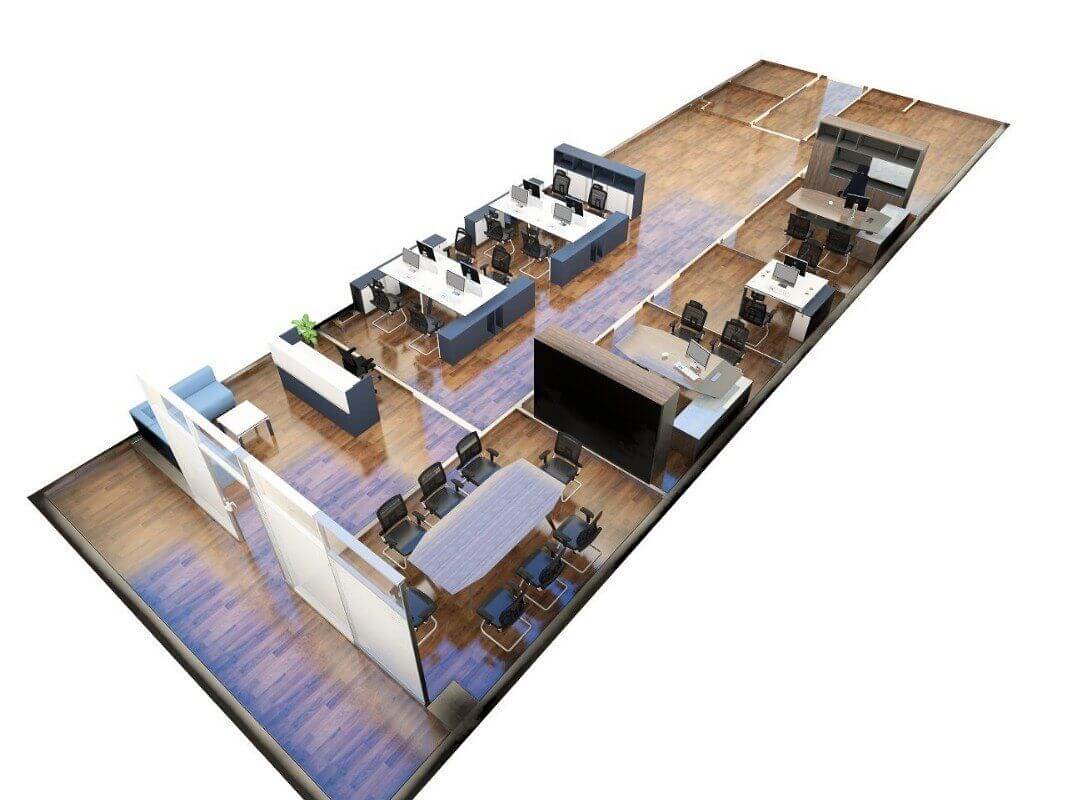

Design teams at high-quality office furniture factories excel at breaking down complex project requirements into executable production parameters. For large-scale office space supporting needs, designers conduct on-site measurements, analyze spatial circulation using architectural drawings, and precisely calculate furniture quantities and specifications for each area. In financial institution projects, for example, counter heights and drawer layouts are designed around tellers' operational workflows; in tech company offices, pre-installed cable channels have become standard features. This in-depth deconstruction ensures project supporting furniture perfectly aligns with spatial functions.

2. Flexible Manufacturing: The Efficiency Code for Large-Scale Customization

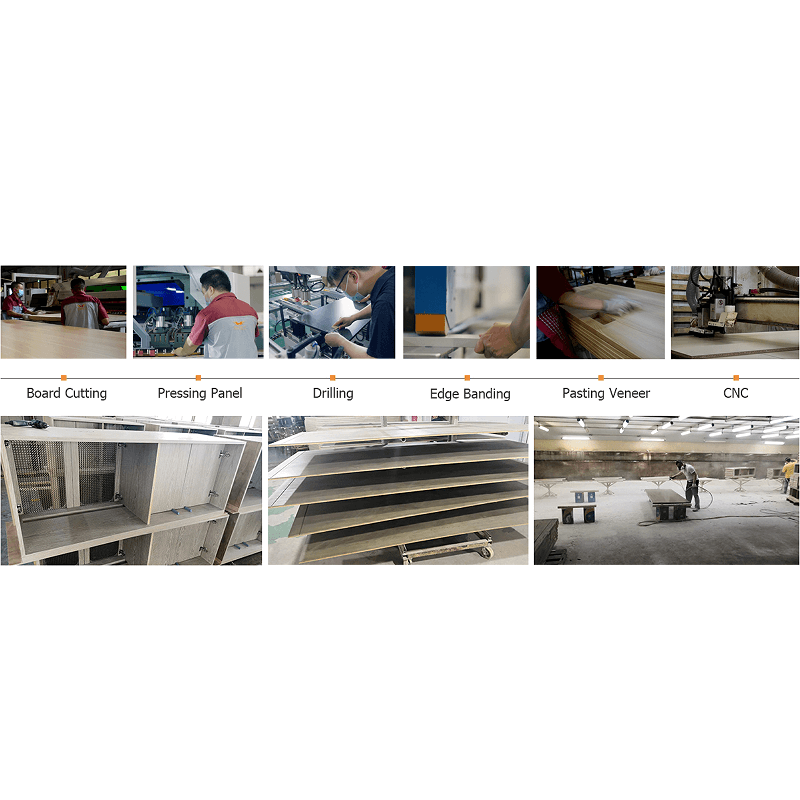

Production workshops in modern office furniture factories adopt modular production systems. CNC equipment converts design drawings into standard components, while differentiated needs for different projects are addressed during assembly. For instance, when an office building project requires 1,000 desks of varying sizes, factories uniformly produce basic components like table legs and surfaces, only adjusting configurations such as panel materials and drawer quantities. This flexible manufacturing model meets customization needs for project supporting furniture while reducing costs through large-scale production.

3. Quality Control Closed-Loop: The Ultimate Guarantee for Project Quality

High-quality office furniture factories establish full-process quality control systems. Raw materials undergo multiple tests (formaldehyde emissions, physical properties) before warehousing; quality checkpoints monitor each production step, including non-destructive testing for welded parts and adhesion tests for paint finishes. Finished products undergo assembly simulations to verify component compatibility and stability. For project supporting furniture, secondary inspections are conducted after on-site installation to ensure no transportation damage occurred.

From needs deconstruction to flexible manufacturing and quality control closed-loops, high-quality office furniture factories transform customization requirements for project supporting furniture into standardized production processes through these three key stages. This ensures both project delivery efficiency and consistent furniture quality—serving as the core of factory competitiveness and a critical guarantee for smooth project advancement.