October 15,2025

admin

When seeking an office furniture factory as a partner for project supporting furniture, poor selection may lead to problems such as delayed schedules and inconsistent quality. How to accurately screen out reliable partners? The following 4 rigorous standards are worth considering.

1. Qualification Certification: Entry Threshold for Project Supporting Furniture

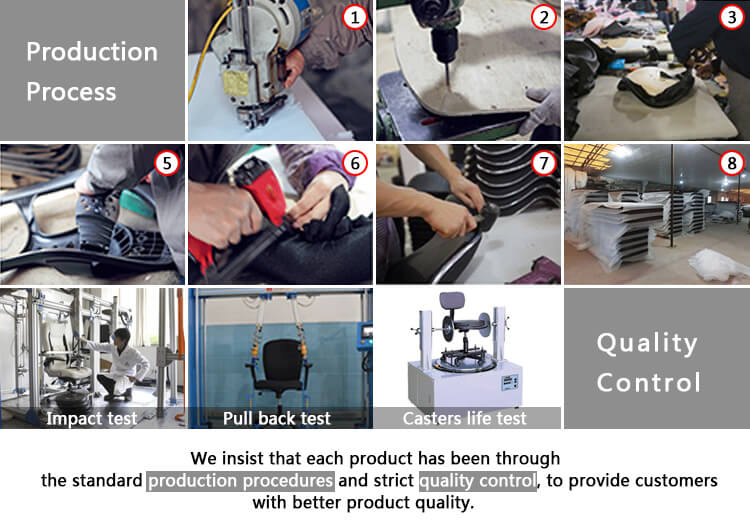

A high-quality office furniture factory must possess complete qualification certificates. ISO9001 quality management system certification indicates standardized production processes, while ISO14001 environmental management certification proves effective environmental protection measures. For project supporting furniture projects, focus should also be placed on the factory's green building material certifications, such as China Environmental Label Certification (Ten-Ring Certification), to ensure furniture meets engineering environmental requirements. Additionally, factories with experience in large-scale engineering projects often have advantages, as their case history demonstrates capability in handling complex needs.

2. Customization Capability: Core Competence for Matching Engineering Needs

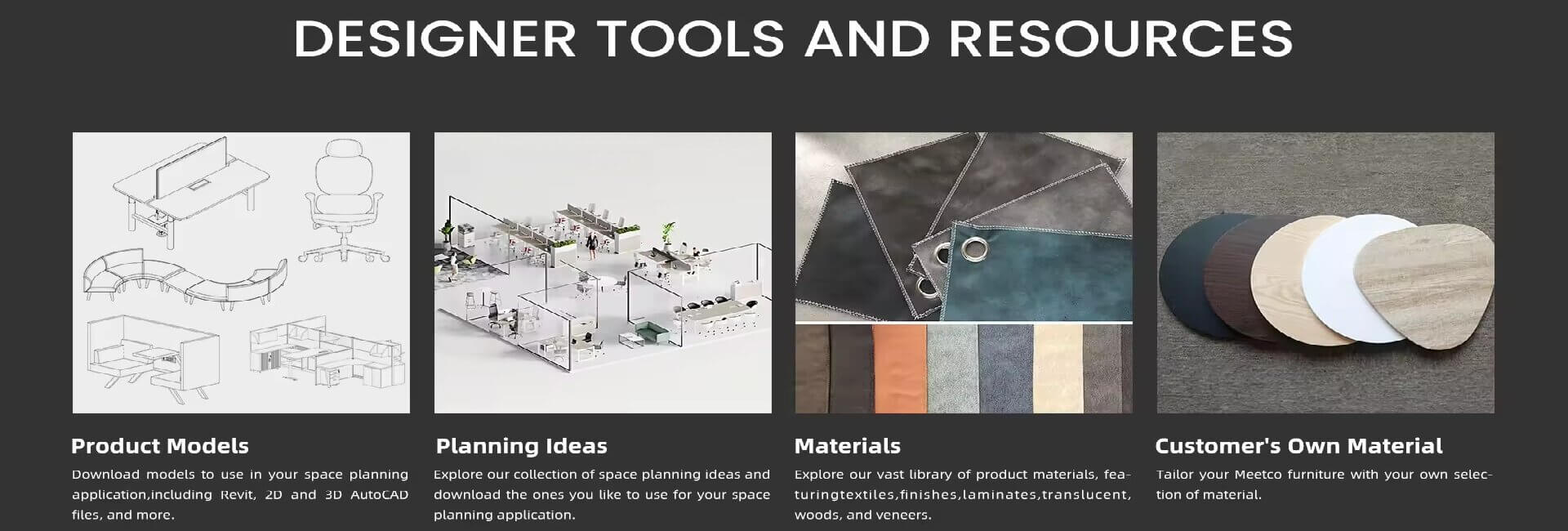

Project supporting furniture usually requires customization based on spatial layout and functional requirements. When evaluating an office furniture factory's customization capability, examine the professionalism of its design team—whether they can provide full-process design services from layout planning to 3D rendering. Production equipment is another key indicator; modern CNC equipment ensures processing precision, with laser cutting machines achieving millimeter-level errors. For needs involving complex shapes or special materials, confirm whether the factory has corresponding technical solutions.

3. Delivery Capability: Critical Guarantee for Project Progress

The delivery cycle of project supporting furniture directly affects overall project progress. A reliable office furniture factory will establish a sound production scheduling system, clarify timelines for each link, and provide progress tracking services. When assessing production capacity, understand the number of equipment, worker scale, and daily output to determine if they can meet the concentrated procurement needs of the project. Furthermore, the logistics and distribution network should not be overlooked—a nationwide warehousing and logistics system ensures furniture is delivered to the construction site safely and on time.

4. After-Sales Service: Solid Backing for Long-Term Engineering Use

After-sales maintenance of project supporting furniture is crucial. A high-quality office furniture factory will offer a warranty period of at least 5 years and commit to 24-hour response to after-sales needs. For large engineering projects, the factory should provide on-site maintenance teams to promptly resolve issues arising during use. Additionally, the ability to support furniture upgrades and transformations is a key consideration—As enterprises develop, project supporting furniture may require layout or functional adjustments, and factories with transformation capabilities can reduce clients' secondary procurement costs.

When selecting an office furniture factory, evaluate through qualification certification for background, customization capability for competence, delivery capability for efficiency, and after-sales service for guarantee. A comprehensive assessment across these four dimensions will secure a truly reliable partner for project supporting furniture, ensuring smooth project progress and long-term usability.